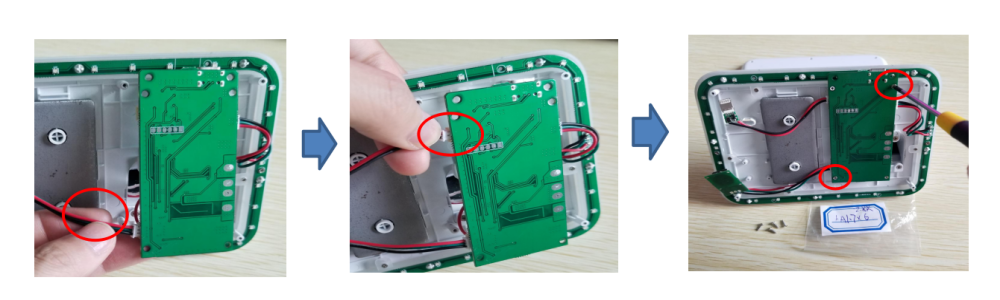

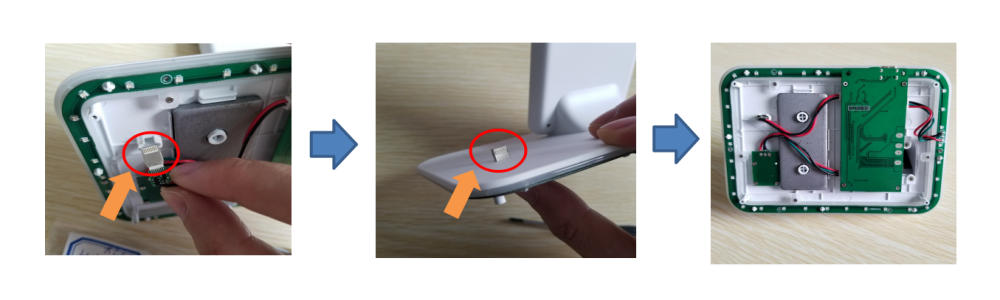

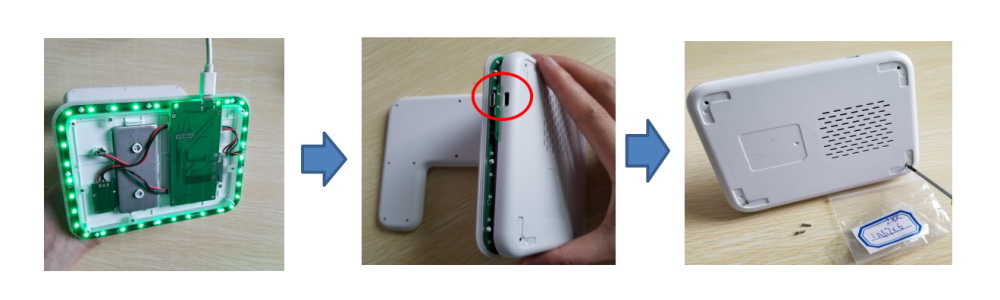

How to assemble the products decided how good the quality is. QC is a means to detect bad quality products, but could not decide which product is good or bad, Assembly does.

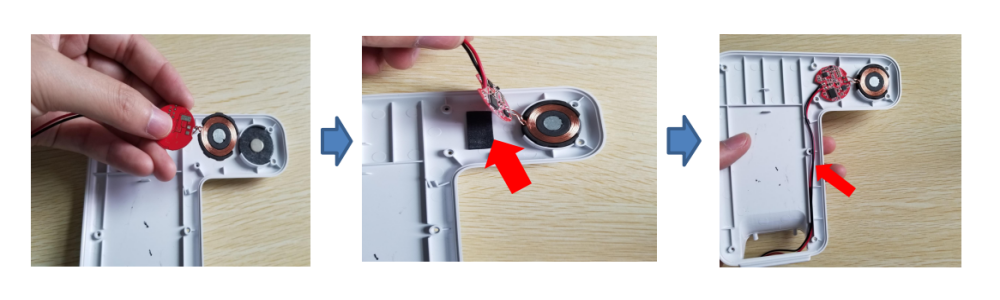

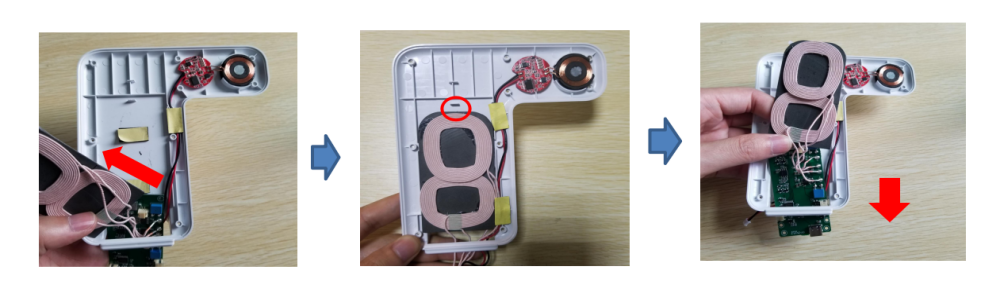

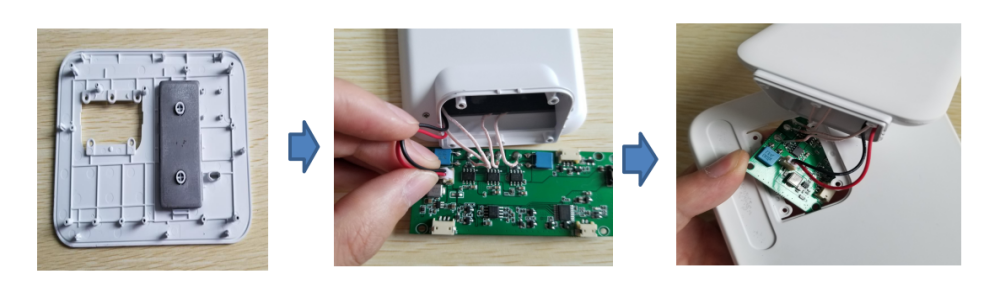

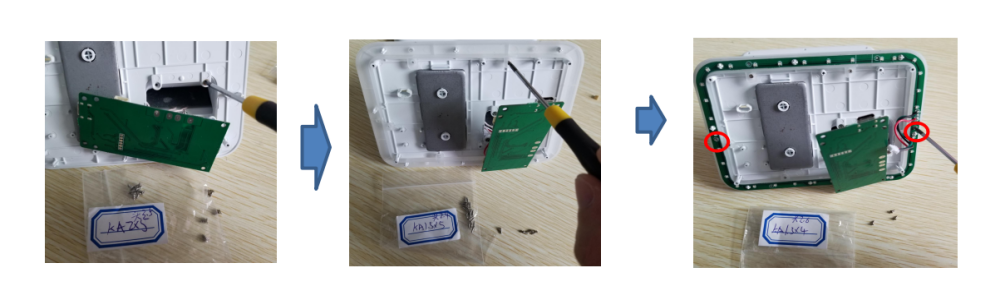

This article is to show how wireless chargers are made. Each step requires 1-3 workers to get each procedure finished to meet good quality and an output of 5000 pcs/day.